Protective stop

No interlock protection outage: in dangerous equipment, equipment without two or more kinds of safety protection devices must be outage! These devices ensure that our body parts will not contact the dangerous parts of the equipment, so the installation must be standardized, it is strictly prohibited to dismantle, shielding!

No grounding leakage protection stop: the shell is not grounded or not installed to meet the requirements of leakage protection switch, electrical equipment to stop using! Such as production use of electrical equipment coating drying box shell to ground, and install leakage protection switch.

No pre-job training stop: employees, technicians and managers who operate dangerous equipment (such as punch press, injection molding machine, die casting machine, etc.) shall stop using the equipment if they have not received safety training or passed the examination before taking the job.

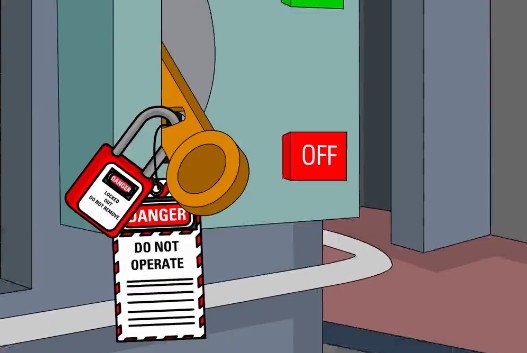

No safe operation procedures stop: the equipment will be stopped if there are no relevant safety operation procedures before, during and after operation. Note: Appropriate personal protective equipment should be worn before operation, and the effectiveness of safety devices should be checked. If any fault occurs during operation, the machine must be shut down and the power must be cut off for professional maintenance. Safety operation procedures are not operation procedures, and the expression should be easy to understand.