Hine law

For every serious accident, there are 29 minor accidents, 300 near-misses and 1,000 potential accidents.

According

to the statistical analysis of the accident, there are few objective

factors, few equipment factors, and most of them are human factors:

there are paralysis and fluke mentality, weak safety awareness, reduced

behavior standards, the site management personnel lack of correct

understanding of safety production, safety responsibility system is not

implemented, there are "two sides" phenomenon between system and

implementation.

Rectification and management of violations include:

Whether

there are rules and regulations affecting production safety or obvious

violations, whether production safety risk identification and prevention

and control are organized as required.

Whether

the process, equipment, design, plan, etc. are changed, whether the

change procedure is strictly implemented, whether the change risk is

identified and controlled.

Whether

there is forced to risk illegal operations, arrange people without

corresponding qualifications to engage in dangerous operations, whether

there is knowingly committed, not follow the rules, there is more than

order, inaction and disorderly acts.

Whether

to confirm the qualification and ability of the contractor's key

personnel, whether to carry out safety analysis and confirm safety

measures before work in high-risk operations, whether to strictly

implement the work permit system, whether to implement the requirements

of on-site supervision.

Whether to confirm the ability of safe operation, post risk prevention and control, emergency response, etc.

Rectification of operation violations include:

Whether

there is a violation of the operation rules, construction plan,

operation process, work steps and other requirements of the behavior.

Whether to wear and use effective labor protection equipment according to regulations.

Whether there is off guard, sleep guard, drunk on guard and other behaviors.

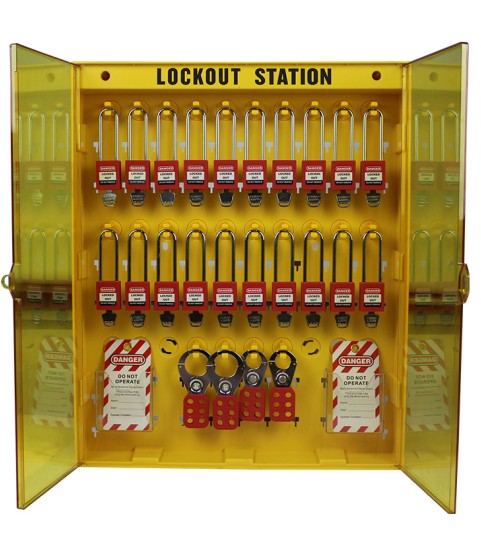

Whether

the standby, idle or to be scrapped process equipment or inspection and

maintenance are effectively purged and replaced, energy isolation,

status identification, Lockout tagout.

Whether

the roving inspection system is strictly implemented, and whether the

abnormal situation, leakage, alarm, risk, hidden trouble found in the

work that obviously affects the production safety are reported and dealt

with in time according to the regulations.