Lockout tagout case

Hand cutting event of diaphragm cutter of coiling machine

The sensor of the front limit of the motor of the diaphragm cutter was abnormal, and the employee stopped the machine to check and found that the sensor was not bright. It was suspected that there was dust shielding. The employee used the front to wipe the sensor without manual operation or Lockout tagout, and the motor acted suddenly in the process, resulting in the right palm being cut by the diaphragm cutter.

safety

1. If the equipment is abnormal, strictly follow the Lockout tagout.

2. When the device is abnormal, it must stop and start manually;

3. Raise your hand and give feedback in time when the access control fails and the device is no longer capable of automatic operation.

The liquid injection employee failed to open the pressure relief valve and was injured by the clamp

When PRD staff used wrench to deal with the breath-holding pull head of No.2 jig of liquid injection machine, the pressure relief valve was deflated without opening. After the anomaly of clamping was eliminated, the clamp moved forward under the action of the remaining air pressure in the cylinder, forming an extrusion area between the pull head and the pull head, and the back of the staff's hand was clipped.

safety

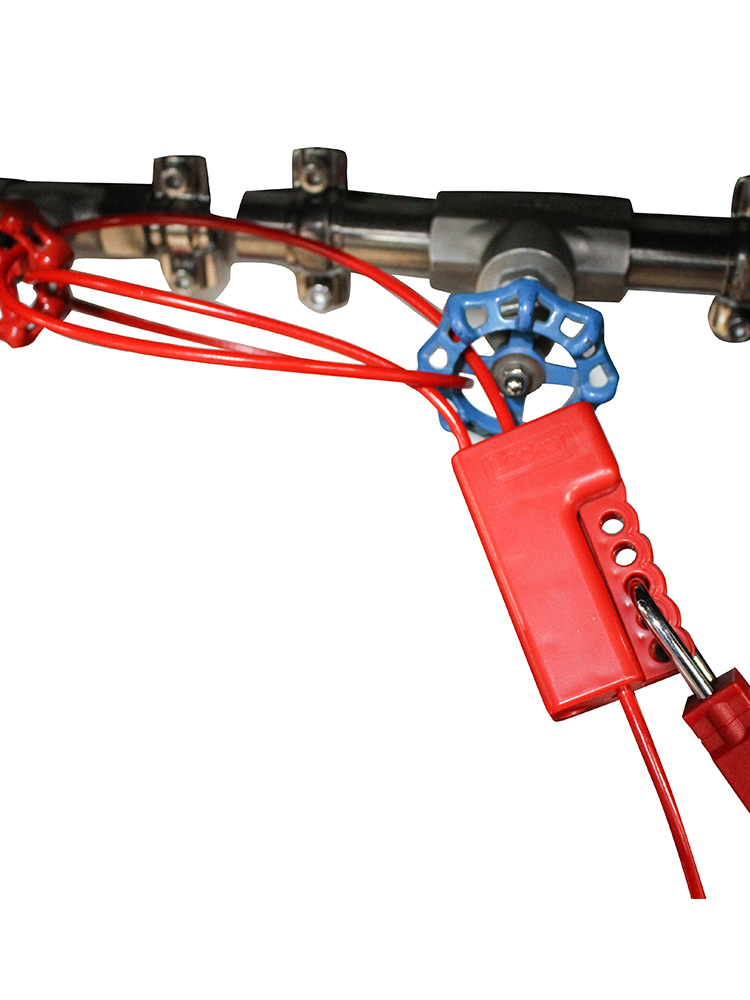

1, when dealing with the blockage problem must be deflated out of the tagout;

2. Raise your hand and give feedback if you can't handle an exception.