1. Purpose

The purpose of the Lockout/Tagout program is to protect Montana Tech employees and students from injury or death from the release of hazardous energy. This program establishes the minimum requirements for isolation of electrical, chemical, thermal, hydraulic, pneumatic, and gravitational energy prior to equipment repair, adjustment or removal. Reference: OSHA Standard 29 CFR 1910.147, the control of hazardous energy.

2. Responsibilities

The Physical Facilities Director has ultimate responsibility for the Lockout/Tagout Program for Physical Facilities Employees, and faculty members who utilize lockout/tagout have responsibility for ensuring the program is followed. The Director/Faculty member must:

Ensure compliance with all hazardous energy-control procedures.

Provide the necessary devices to lockout or tagout energy-isolating devices

Employees or students who utilize lockout/tagout must:

Be familiar with the purpose and use of lockout/tagout procedures and will be responsible for ensuring they do not attempt to restart or reenergize machines or equipment that are locked out or tagged out

Be able to recognize and control hazardous energy sources and implement established lockout or tagout procedures

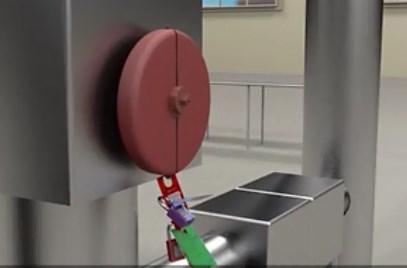

3. General Lockout/Tagout Procedures

Before working on, repairing, adjusting or replacing equipment and machinery, all appropriate safety procedures, including lockout/tagout, must be utilized to place the machinery or equipment in a neutral or zero mechanical state.

When the energy-isolating device is not lockable, a tagout system may be used, provided the level of safety is equivalent to the level of safety using a lockout system.procedures.

Montana Tech must supply the lockout and tagout devices required.

exceptions to the lockout/tagout procedures.

lockout/tagout procedures for the boilers at Montana Tech.